PRODUCT EXAMPLES

PRODUCT

Tukasa Industries has supplied various products for pharmaceutical, beverage, food, and chemical plants. We aim to deliver our cultivated technology to many users and apply it effectively. From small piping to large-scale projects, we strive to provide broad support and continuously innovate to meet your needs.

Sanitary Stainless Steel Piping

Due to delivery constraints, the maximum length we can handle is 1.5m. For lengths exceeding 1.5m, please consult us directly. We also offer buff polishing, electro-polishing (with certificate), and pickling.

*Material options include SUS304 for sanitary piping and SUS316L for general stainless steel piping.

Product 01:

Sanitary Straight Piping

- Main Specifications

- Both ends with ferrules

- SUS316L 8A~ Price: From ¥10,000~

- Shortest delivery: 1 day

- Minimum length: 42mm

Product 02:

Sanitary Piping [One-Side L-Shaped Pipe]

- Main Specifications

- One-side L-shaped pipe

- SUS316L 1.0S~ Price: From ¥12,000~

- Shortest delivery: 1 day

Product 03:

Sanitary Piping [Straight Pipe]

- Main Specifications

- Straight pipe

- Both ends flanged

- SUS316L 20A~ Price: From ¥15,000~

- Shortest delivery: 1 day

Product 04:

Sanitary Piping [Ferrule Flange Conversion]

- Main Specifications

- Ferrule flange conversion

- SUS316L 1.0S x 20A~ Price: From ¥12,000~

- Shortest delivery: 3 days

Product 05:

General Stainless Steel Piping [L-Shaped Pipe]

- Main Specifications

- L-shaped pipe

- Both ends flanged

- SUS304 20A~ Price: From ¥7,000~

- Shortest delivery: 1 day

Product 06:

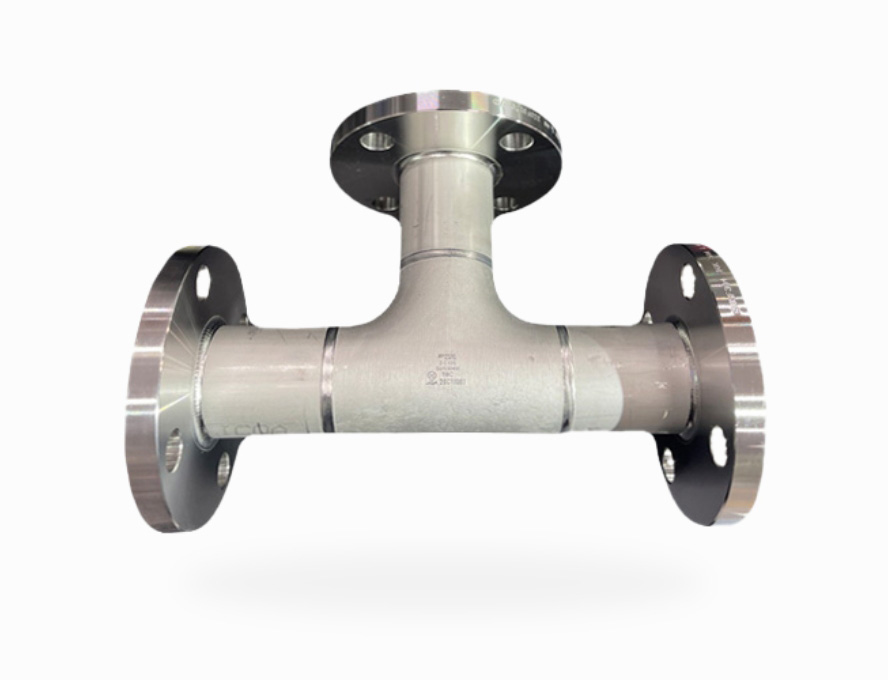

General Stainless Steel Piping [T-Shaped Pipe]

- Main Specifications

- T-shaped pipe

- Both ends flanged

- SUS304 20A~ Price: From ¥9,000~

- Shortest delivery: 2 days

- Shipping Costs

- Shipping starts at ¥1,000 (for sizes within 160 cm total length and 25 kg weight). Cash on delivery is available. For other sizes, please inquire.

- Order Quantities

- Orders can be placed from a single unit. Detailed estimates will be provided within two days. For urgent orders, please contact us directly by phone. We also handle custom welding specifications and other special requests.

Other Production Examples

We handle various piping processes, including burring. We also manufacture tanks, frames, stainless steel products, and various units. Please feel free to contact us.

- Please Check Before Ordering

-

-

1.Dimensions and Tolerances

Precision requirements vary depending on your order and delivery date. If you have any concerns, please consult us in advance. -

2.Exchanges

Please note that cancellations cannot be made after shipment. -

3.Certificates

Certificates for electro-polishing, degreasing, and mill sheets (material certificates) can be issued upon request.

-

FAQ

- Q: Are weekend services available?

-

A:

Yes, we offer services on weekends.

- Q: Do you accept factory tours?

-

A:

Yes, factory tours are available. Please feel free to consult us. Detailed access information and visitor parking are provided.

- Q: Can you produce welding sample pieces?

-

A:

Yes, we can provide welding samples before giving a formal estimate. You can view some samples at our headquarters during your visit.

- Q: Can I order just one prefab unit?

-

A:

Yes, we accept small lot and single unit orders. If urgent, please call us in advance.

- Q: What is the fastest delivery time for prefab units?

-

A:

Depending on the specifications, if contacted in the morning, we can ship the same day. For urgent cases, we prepare for the quickest possible dispatch.

Note: This does not include electro-polishing or passivation. Please inform us if these processes are needed. I will provide you with the revised delivery time including the necessary processes.

- Q: Can you create custom fittings without drawings?

-

A:

Yes, we can handle custom fittings after a consultation. Please feel free to consult us even if you don’t have drawings.

- Q: What areas do you serve?

-

A:

We offer nationwide service, from Hokkaido to Kyushu.

- Q: Can I purchase only instruments or pumps?

-

A:

Yes, we can provide only the necessary instruments or pumps.

- Q: Can you handle maintenance only?

-

A:

Yes, we can provide maintenance services alone.

- Q: Do you provide calibration services?

-

A:

Yes, we offer calibration for pressure and temperature gauges.

- Q: What is your quality control system like?

-

A:

Quality inspections are conducted at three stages: provisional attachment, welding, and pre-delivery packaging. Checks are done by responsible staff at each stage, with final inspection by a manager before shipment.

- Q: an you work with different materials?

-

A:

Yes, we work with iron materials, titanium alloys, and various stainless steels.

- Q: Can you handle resin materials?

-

A:

Yes, we handle PVC, PE, and Teflon materials.

- Q: Can you produce supports and tanks?

-

A:

Yes, we manufacture tanks from small capacities and support structures, including FRP. For large tanks, please consult us.

- Q: Can you handle insulation work only?

-

A:

Yes, we can handle insulation for even a single pipe.

- Q: Can you perform ancillary work only?

-

A:

Yes, we can handle everything from on-site surveys and CAD drawings to surface treatment after pipe fabrication.

- Q: Can you handle only installation work?

-

A:

Yes, we are qualified for machinery and equipment installation work.

- Q: What industries do you primarily serve?

-

A:

We have experience in pharmaceuticals, food and beverage, and chemical plants.

BUSINESS DETAILS

CONTACT

Please feel free to contact us with any requests, questions or consultations.

View All