- HOME

- FACTORY

FACTORY

At our company, we have established an equipment system that maximizes our cultivated technology, creating more hygienic and high-quality products for pharmaceutical, beverage, food, and chemical plants.

MACHINE

/ Introduction of Equipment

Machine 01:

Laser Welding Machine

We used to proceed with the fabrication of unit bases using a bandsaw and manual TIG welding. However, TIG welding generates significant distortion in the units due to welding heat, requiring a process of welding, cooling, and repeating.

This laser welding machine has a narrow weld width and heat spreads vertically, resulting in minimal distortion during the welding of unit bases. The reduced distortion greatly shortens the production time for unit fabrication.

Furthermore, the laser welding machine does not require the skills of a skilled welder; even those without experience can weld as easily as drawing lines with a ruler.

- Main Specification

- CHU-LW2000

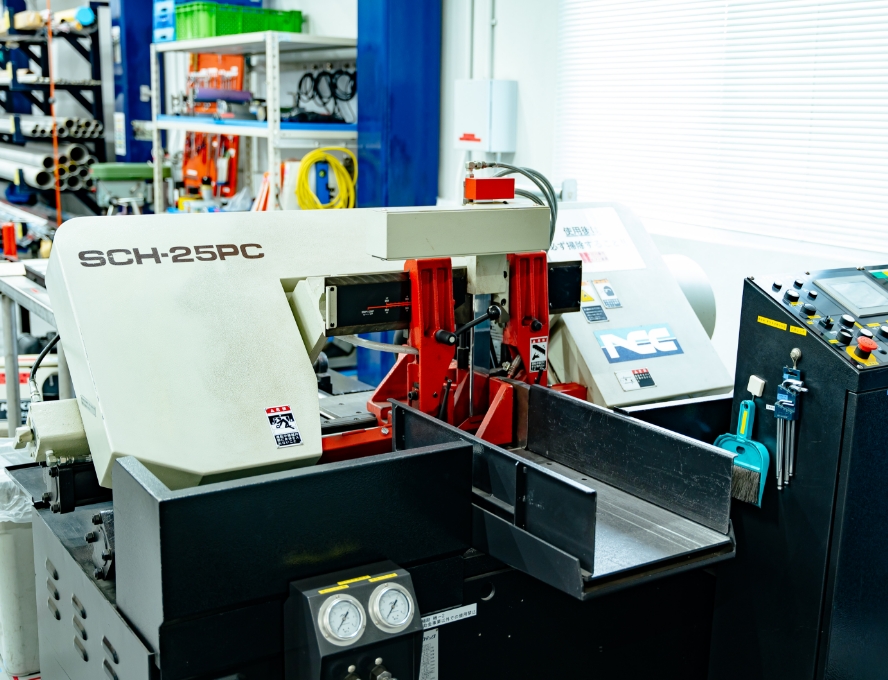

Machine 02:

Band Saw Machine

A bandsaw significantly improves the cutting speed for piping materials like square pipes. It is essential machinery for producing units that incorporate piping in-house. While the fabrication of unit bases was previously outsourced, this equipment enables us to handle it internally.

- Main Specification

- Niko Tech SCH-25PC

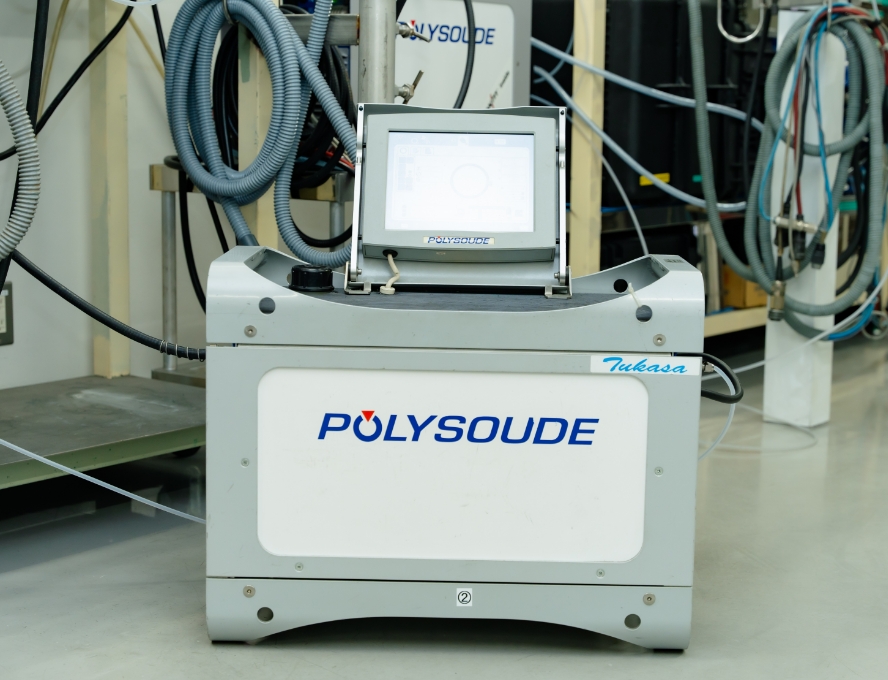

Machine 03:

Automatic Welding Machine

Polysoude automatic welding machines replace traditional manual welding. It dramatically improves piping welding speed without relying on skilled operators. Additionally, the weld finish is consistent without the variability seen in manual welding by skilled workers, achieving standardized quality.

- Main Specification

- Polysoude P4 (3 units),

- P6 (1 unit),

- PS164 (1 unit),

- Babu Hitachi 8DP-220 (1 unit)

5SPROJECT

/ Commitment to 5S Activities

At our company, we conduct 5S activities in the manufacturing of items delivered to our valued customers. Cleanliness and organization in the manufacturing environment are also part of our service. We thoroughly organize and tidy up our factory to provide services that reassure our customers.

MANAGEMENT

/ Management System

Information Sharing with a Unique

Management System

We use a unique management system to share information on progress, daily reports, overtime, and delivery status, ensuring all staff have up-to-date information for quick and accurate responses to customers.

Implementation of Centralized Management

At Tukasa Industries, we implement centralized management through our proprietary management system. In addition to process and document management, we manage document data through cloud storage and handle various applications such as attendance management and requests through our internal system. This allows us to handle various tasks consistently, even while on business trips to distant sites.

Furthermore, through regular improvements to our centralized management system, we continuously review and enhance our operations.

-

IT-Based Management of Attendance and Business Trips

We have digitized management operations. -

Cloud Data Management of Manufacturing Drawings

-

Daily business reports are visualized.

-

Remote Response via Cloud Management

-

We use a contactless face recognition system.

-

Provision of iPhones to All Employees

Paperless processing for various internal applications

Documents such as daily reports, overtime, and leave requests are electronic at Tukasa Industries. These requests and documents are handled through a system-based application and approval process, allowing submissions regardless of time or location.

Internal notifications and communications are also centralized within our management system, ensuring that all staff members, whether internal or external, can access the latest information at any time.

Digitization of Internal Manuals

We promote the digitization of internal manuals, ensuring access to operational content anytime, anywhere.

CONTACT

Please feel free to contact us with any requests, questions or consultations.

View All